The production and disposal of oily sludges are considered as one of the most critical environmental issues in the petroleum industry, particularly in the petroleum producer countries. Annually, large quantities of oily sludges (more than 60 million tons) are generated and more than 1 billion tons of oily sludge has been accumulated worldwide.

Oily sludge in refineries

In particular, the sludge generated during the petroleum refining process has received increasing attention in recent years. It has been estimated that one ton of oily sludge is generated for every 500 tons of crude oil processed. Oily sludge is a complex and variable hazardous waste depending on the quality of crude oil as well as the processes used for water-oil separation. In general, oily sludge is composed of 40-52% alkanes, 28-31% aromatics, 8-10% asphaltenes, and 7-22.4% resins by mass. In addition, the oily sludge contains the heavy metals such as Zn, Cd, Pb, Cr, Cu, Ni and V.

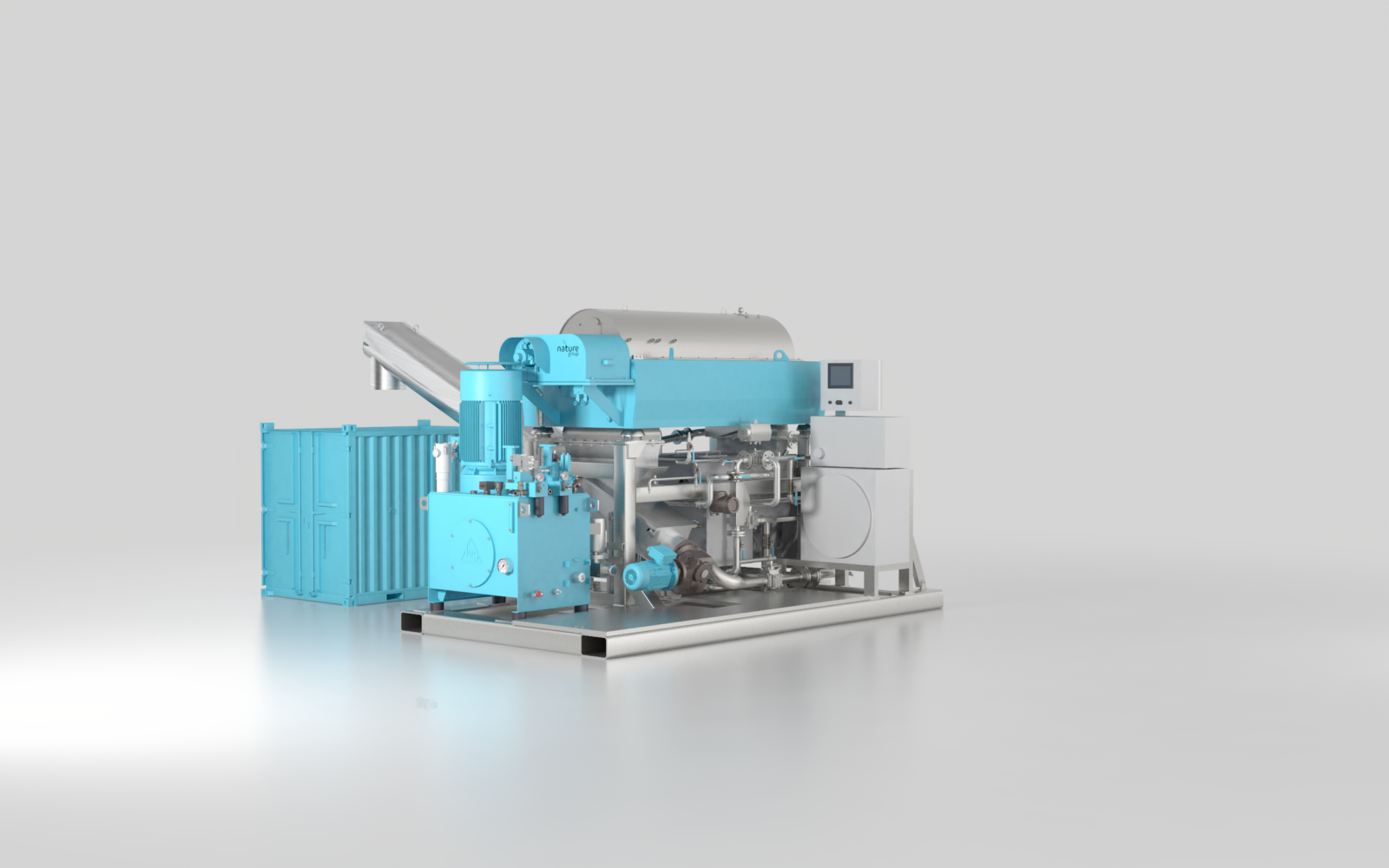

Because of variations in the chemical composition of oily sludges, its physical properties such as density, viscosity, and heat value can vary significantly. Based on the integrated waste management strategy, three approaches including source reduction, oil recovery and disposal using different technologies such as thermal processes and biodegradation have been reported for oily sludge treatment.

Economical and good news for the environment

The development of environmentally friendly and economical technology for oily sludge management and treatment has for years been on the agenda of being a necessary achievement of sustainable development in the petroleum industry.